Rubber elasticity, plastic moldability and damping performance

SEPTON™ and HYBRAR™

- General name

- Hydrogenated styrenic thermoplastic elastomers

- Sales format

- Pellet/powder

SEPTON™

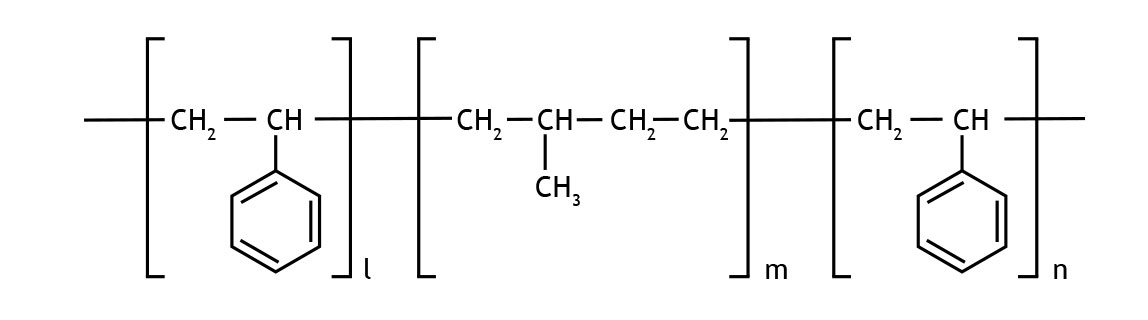

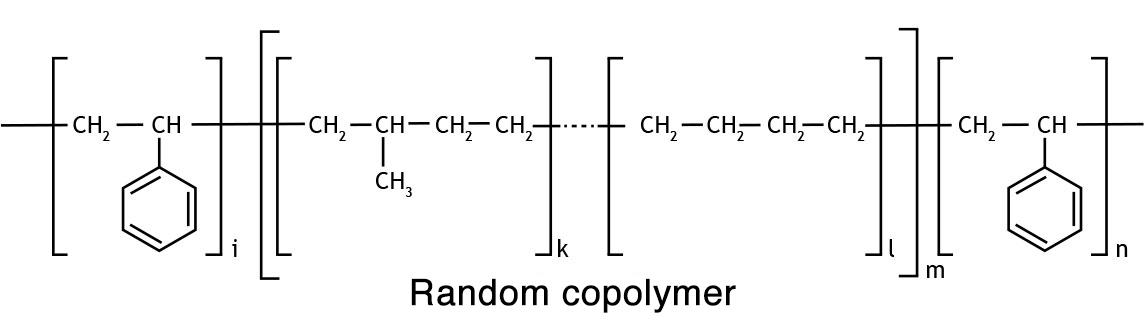

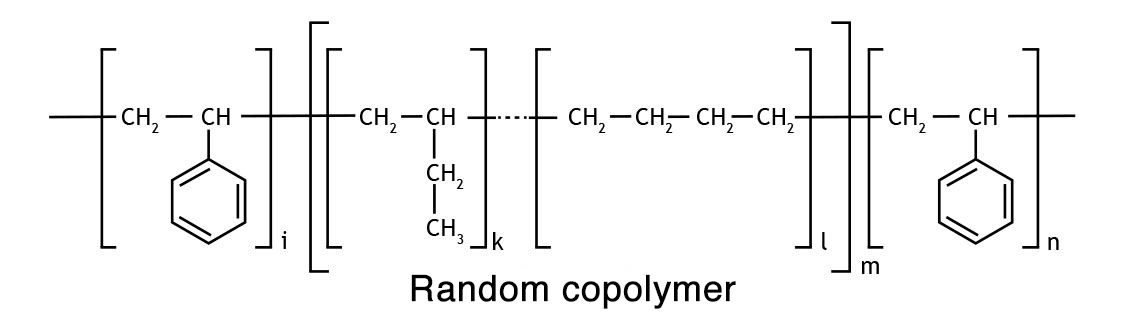

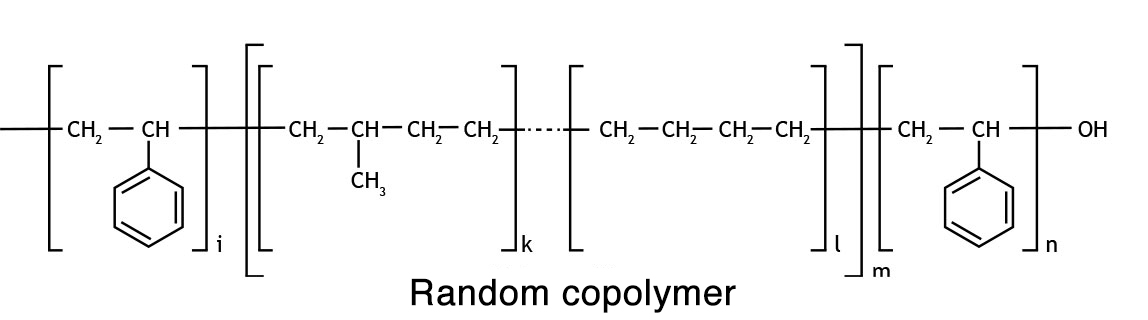

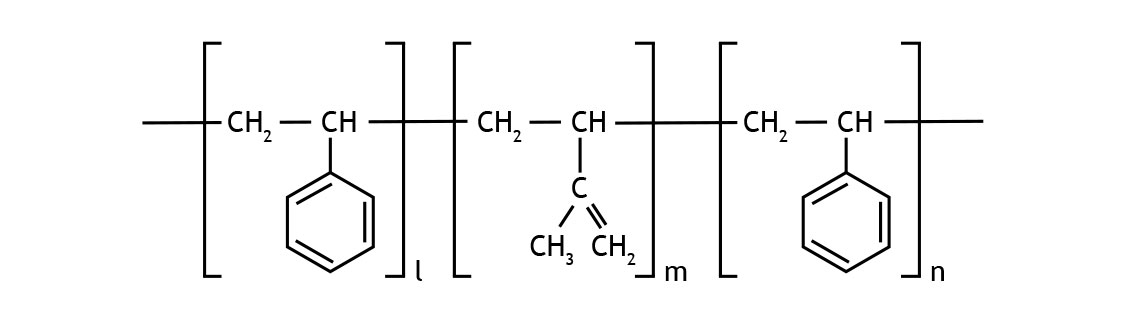

SEPTON™ is a styrenic thermoplastic elastomer developed by Kuraray. It is a block copolymer that consists of styrene-based hard-blocks and a diene soft block. SEPTON™ is used in a variety of TPE compounds. SEPTON™ can be processed in a wide variety of forms, including consumer goods, soft touch grips and automotive components.

HYBRAR™

HYBRAR™ is a triblock co-polymer with polystyrene end blocks and a vinyl bonded rich polydiene mid-block. HYBRAR™ exhibits high vibration damping and shock absorption properties. HYBRAR™ can be processed in a wide variety of forms, including films, tubes and injection molding.

Applications

SEPTON™

TPE compounds

Adhesives, coatings and sealants

Wires, cable skin material

Automotive parts

Fabrics, nonwoven materials

Plastics modifiers, compatibilizers

Medical parts

Toys, sporting goods

Elastic film

Electronic parts

Soft touch applications, grips

Gels

Packaging materials

HYBRAR™

Sporting goods

Damping and noise absorbing components

Household appliances

Automotive parts

Medical parts (films, sheets, tubes)

Pressure-sensitive adhesives, coating agents, sealing materials

Extrusion molded products

Flooring

Shoe components

Soft touch goods

Foam damping materials

Characteristics

SEPTON™

Thermoplastic rubber that possesses high elasticity, high strength, weather resistance, low temperature properties, chemical resistance (acid, alkali, alcohol), heat aging resistance, and electrical property (insulation). It is also recyclable.

HYBRAR™

Delivers robust damping performance at room temperature and has an affinity with polyolefin and polystyrene.

Thermoplastic with excellent moldability.

Can be cross-linked similar to rubber.

Possesses rubber elasticity similar to vulcanized rubber.

Hydrogenated grade (7000 series) provides excellent transparency as a polypropylene blend.

Offers excellent weather resistance and heat resistance.

Can be used as a soft compound that does not include a plasticizing agent.

Standard grades and properties

SEPTON™ grades

| Grade | Type | Styrene content | MFR | Solution viscosity (Toluene Solution 30ºC) |

Physical form | Hardness (Type A) |

|||

|---|---|---|---|---|---|---|---|---|---|

| 230ºC, 2.16 kg (g/10min) |

200ºC, 10kg (g/10min) |

5wt% (mPa•s) |

10wt% (mPa•s) |

15wt% (mPa•s) |

|||||

| 1020 | SEP | 36 | - | 1.8 | - | 42 | - | Powder | 70 |

SEPTON™ 1000 series is a di-block type with excellent transparency and flow ability. Mainly used as an adhesive, sealing material, automotive part, wire cable filling agent and unsaturated polyester modifier.

| Grade | Type | Styrene content | MFR | Solution viscosity (Toluene Solution 30ºC) |

Physical form | Hardness (Type A) |

|||

|---|---|---|---|---|---|---|---|---|---|

| 230ºC, 2.16 kg (g/10min) |

200ºC, 10kg (g/10min) |

5wt% (mPa•s) |

10wt% (mPa•s) |

15wt% (mPa•s) |

|||||

| 2002 | SEPS | 30 | 70 | 100 | - | - | 25 | Pellet | 80 |

| 2004F | SEPS | 18 | 5 | - | - | - | 145 | Pellet | 67 |

| 2005 | SEPS | 20 | No flow | No flow | 40 | 1700 | - | Powder | - |

| 2006 | SEPS | 35 | No flow | No flow | 27 | 1220 | - | Powder | - |

| 2063 | SEPS | 13 | 7 | 22 | - | 29 | 140 | Pellet | 36 |

| 2104 | SEPS | 65 | 0.4 | 22 | - | - | 23 | Pellet | 98 |

The SEPS structure generally does not crystallize and exhibits excellent tensile elongation and low temperature properties. The SEPTON™ 2000 series features a variety of hard grades for use in many areas including personal care products, medical products, automotive parts, films and adhesives.

| Grade | Type | Styrene content | MFR | Solution viscosity (Toluene Solution 30ºC) |

Physical form | Hardness (Type A) |

|||

|---|---|---|---|---|---|---|---|---|---|

| 230ºC, 2.16 kg (g/10min) |

200ºC, 10kg (g/10min) |

5wt% (mPa•s) |

10wt% (mPa•s) |

15wt% (mPa•s) |

|||||

| 4033 | SEEPS | 30 | <0.1 | <0.1 | - | 50 | 390 | Powder | 76 |

| 4044 | SEEPS | 32 | No flow | No flow | 22 | 460 | - | Powder | - |

| 4055 | SEEPS | 30 | No flow | No flow | 90 | 5800 | - | Powder | - |

| 4077 | SEEPS | 30 | No flow | No flow | 300 | - | - | Powder | - |

| 4099 | SEEPS | 30 | No flow | No flow | 670 | - | - | Powder | - |

The SEPTON™ 4000 series (SEEPS) series (SEEPS) offers better tensile strength, oil retention and PE compatibility than SEBS.

Additionally, the SEPTON™ 4000 series features a variety of molecular weight grades. The high molecular weight version provides robust tensile strength and compression set. Used in many applications including gels, films and automotive parts.

| Grade | Type | Styrene content | MFR | Solution viscosity (Toluene Solution 30ºC) |

Physical form | Hardness (Type A) |

|||

|---|---|---|---|---|---|---|---|---|---|

| 230ºC, 2.16 kg (g/10min) |

200ºC, 10kg (g/10min) |

5wt% (mPa•s) |

10wt% (mPa•s) |

15wt% (mPa•s) |

|||||

| 8004 | SEBS | 31 | <0.1 | <0.1 | - | 40 | - | Powder | 80 |

| 8006 | SEBS | 33 | No flow | No flow | 42 | - | - | Powder | - |

| 8007L | SEBS | 30 | 2.0 | - | - | 20 | - | Pellet | 77 |

The SEPTON™ 8000 series (hydrogenated SEBS type) possesses appropriate tensile strength and is used in adhesives, automotive parts, personal care products and more.

| Grade | Type | Styrene content | MFR | Solution viscosity (Toluene Solution 30ºC) |

Physical form | Hardness (Type A) |

|||

|---|---|---|---|---|---|---|---|---|---|

| 230ºC, 2.16 kg (g/10min) |

200ºC, 10kg (g/10min) |

5wt% (mPa•s) |

10wt% (mPa•s) |

15wt% (mPa•s) |

|||||

| HG252 | SEEPS- OH |

28 | 26 | - | - | - | 70 | Pellet | 80 |

SEPTON™ HG252 features a hydroxyl group on one end and is used as a polar resin modifier and a polar/non-polar resin compatibilizer.

HYBRAR™ grades

Non-hydrogenated grades

| Grade | Type | Styrene content | Tg | MFR | Solution viscosity (Toluene solution 30ºC) |

Physical form | Hardness (Type A) |

|||

|---|---|---|---|---|---|---|---|---|---|---|

| 190ºC, 2.16 kg (g/10min) |

230ºC, 2.16kg (g/10min) |

15wt% (mPa•s) |

20wt% (mPa•s) |

30wt% (mPa•s) |

||||||

| 5125 | Vinyl-bond rich SIS | 20 | -13 | 4 | - | - | 100 | 650 | Pellet | 60 |

| 5127 | Vinyl-bond rich SIS | 20 | 8 | 5 | - | - | - | 540 | Pellet | 84 |

HYBRAR™ is a proprietary block copolymer that consists of a polystyrene hard block and vinyl-polydiene soft block.

It exhibits high damping performance at room temperature because its glass transition temperature falls in this range.

Taking advantage of this damping performance, it is used in damping foam sealants and sports products. Other potential applications are electronic parts, building materials, household appliances, automotive parts, adhesives, coating agents and sealing materials.

Hydrogenated grades

| Grade | Type | Styrene content | Tg | MFR | Solution viscosity (Toluene solution 30ºC) |

Physical form | Hardness (Type A) |

|||

|---|---|---|---|---|---|---|---|---|---|---|

| 190ºC, 2.16 kg (g/10min) |

230ºC, 2.16kg (g/10min) |

15wt% (mPa•s) |

20wt% (mPa•s) |

30wt% (mPa•s) |

||||||

| 7125F | Vinyl-bond rich SEPS | 20 | -15 | 0.7 | 4 | - | 55 | 350 | Pellet | 64 |

| 7311F | Vinyl-bond rich SEEPS | 12 | -32 | 0.5 | 2 | 90 | 240 | - | Pellet | 41 |

HYBRAR™ features hydrogenated grades (7000 series) and non-hydrogenated grades (5000 series). In particular, the hydrogenated grades provide excellent heat resistance and weather resistance. HYBRAR™ has good compatibility with polypropylene, and related blends offer excellent transparency with good flexibility.It is used in films, sheets, tubes, and other products as an environmentally friendly softener material without the need for a plasticizer, in contrast to soft PVC.

Catalogues/technical data

Related website

Contact us

Click here for inquires (SEPTON™ and HYBRAR™)- Septon Sales Promotion and Planning Department, Elastomer Division

- Tokiwabashi Tower, 2-6-4, Otemachi, Chiyoda-ku, Tokyo, 100-0004, Japan

Tel.: +81-3-6701-1601

E-mail: elastomer.info@kuraray.com